Heat Pumps - how do they work? - 55

The heat pump has become an attractive and increasingly popular alternative to the conventional boiler, especially now that grants are available in NI to install one in your home...

A method of heating first developed in the USA in the 1940s, the technology has slowly spread across the world and in some countries, notably Sweden, is now the main form of home heating in rural areas. In Germany and Austria it has also gained in popularity.

So how does it work? The first thing to remember is that energy is never lost - it will simply change how it appears - heat is one form of energy but so are fuel, light or electricity. For instance, when you turn on a light bulb the energy brought to it by electricity is converted to light and heat.

Now imagine being given 3kg of meat at 12°C and being asked to heat yourself with it. Impossible? Not if you have a freezer or fridge freezer. Put it in the freezing compartment then sit with your back against the rear of the fridge. As the meat drops in temperature (energy being taken from it), it is rejected at the back of the fridge/freezer in a form that can heat you! The fridge did no more than convert low grade heat energy to high grade.

Heat pumps work in exactly the same way as a fridge. They 'move' heat from one place to another.

Performance

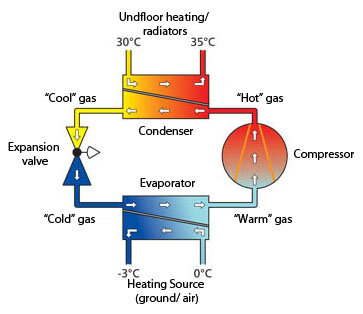

For ground and water source heat pumps there are two circuits: the external 'collector' circuit that pumps a liquid around a piped circuit in the soil or water to collect the heat, and the internal heat pump circuit, filled with refrigerant, that 'moves' the heat.

In place of the external circuit, air source heat pumps simply blow the air across a heat exchanger filled with refrigerant using a big fan.

The internal circuit absorbs the collected heat from the external circuit in an evaporator. As the refrigerant has a low temperature boiling point, it can evaporate into a gas when it is not under pressure. As it evaporates, it absorbs energy in the form of heat (in a similar way to the water in your kettle, which absorbs electrical energy as heat to boil and produce steam).

The refrigerant is now pressurised in an electrical compressor (this is where most of the electrical energy is used). Under pressure, the refrigerant condenses, turns into liquid and releases heat energy. The released heat is normally transferred to water and pumped around the house for space heating and hot water.

The final stage of the internal heat pump circuit is for the refrigerant to pass through an expansion valve, releasing the pressure, allowing it to evaporate again and continue the cycle.

The energy used by the compressor, in a well designed system, is much less than the heat generated and so there is a high performance gain. This is known as the COP or coefficient of performance and can be anything up to 5:1; that is, you get 5kW of heat from just 1kW of electrical power. This, however, is a maximum figure.

If you compare this to a traditional boiler, the benefits are clear. For every unit of energy (gas, oil or solid fuel) a boiler consumes, it will only be able to convert 80% to 95% of that energy into useful heat. A heat pump uses one unit of electricity to produce four or five times as much heat, thanks to the fact that it extracts heat from the ground/air/water. That is, a heat pump's efficiency will range from 250% (COP of 2.5) to 500% (COP of 5).

Test centres in Europe recognised by the European Heat Pump Association, e.g. Buchs laboratory in Switzerland or Arsenal research centre in Austria, will provide approved efficiency certification for a wide range of heat pumps.

Typical COPs for domestic heat pumps range from 2.5 to 4, although if correctly designed and installed that figure should rise to 3.5. The critical factors determining the efficiency of the system are the performance of the heat pump itself and the input and output temperatures: the narrower the range of temperature between the source and the house, the more efficiently the system runs. Thus the smaller the heat lift you need to achieve, the more efficient the heat pump will be. However, heat pumps continue to work effectively even at sub-zero temperatures.

Compression and Vapour Injection Technologies

A good heat pump using compression technology will easily achieve its stated objective of raising water temperatures to 35°C at a COP of 4, sometimes even higher. But for every 1°C extra heat you require, the efficiency of the heat pump drops by around 3%. The temperature lift required is itself dependent on a number of factors.

Firstly, the external ground or air temperature, which may vary by 10°C or more, depending on weather conditions and the depth at which the ground loop is installed, if ground source, or bore hole if geothermal.

Secondly, the temperature of the water circulating in your home. The effect of turning up the room thermostat (higher flow temperature) is to reduce the COP (efficiency) thus the average COP of a heat pump throughout the year can be considerably less than that advertised. This can be mitigated by weather compensation settings. Obviously, a reduction in the efficiency adds to running costs and hence lengthens the payback time.

The correct approach is to ensure the heat pump is suited to its task and is not required to heat water above 35°C/45°C, at which point vapour injection technology should be incorporated (see below). This is most easily achieved by restricting it to space heating, or if water heating is required as well, combining carefully with another system.

A possible answer for ground source heat pumps is to increase the area of the source collector (but this will incur a considerable increase in capital cost), allowing it to recover temperature more easily and therefore provide a higher seasonal performance. Most systems are designed to a return temperature of no less than 2°C to 3°C.

The increasing cost of electricity and poor COP make heating water using conventional heat pumps virtually uneconomic. However if you avail of vapour injection technology, which is an add on to the compression cycle, suppliers say that high seasonal performance can be achieved because the heat pumps are designed to deliver high flow temperatures (up to 65°C).

Using this technology it is possible to achieve a COP of 3.5 while producing heat and hot water at 50°C (to standard EN2SS-3); using a DX coil you may even achieve 65°C and a COP of 3.4. Also, air to water heat pumps are available which have the capacity to deliver 100% of the required heat and hot water while at the same time offering a COP of 4.4, as long as the air source temperature does not fall below 2°C.

Selecting the most suitable heat pump is most important due to the variation in performance and output and the requirement to include or exclude various technologies depending on the particular project. Heat pumps designed precisely for your home will further improve performance and ensure longevity.

Where the energy comes from: air, water or soil

A heat pump is essentially a device that moves heat from one place to another. It can be used to make things either hot or cold and is the technology that operates both air conditioning systems and fridges. They are classified according to how they source the energy required to produce heat and hot water. When collecting heat from the ground (geothermal energy is that which is "stored in the form of heat beneath solid earth"), there's two options, vertical bore holes or horizontal collectors.

A geothermal heat pump (vertical bore hole) uses the heat from the earth's core; this method is useful if the site is small but it's among the more expensive options due to the need for drilling. You will typically need 15m to 100m deep holes; you can drill multiple bore holes rather than a very deep one. The hole(s) will usually be 140mm in diameter, back filled with 80% silica and 20% bentonite, known as 'grouting'. With geothermal heat pumps, the temperature of the ground becomes the datum upon which the system is designed. The refrigerant evaporates at a temperature lower than the datum so that we can use the heat differential and transfer the energy into a smaller volume of water at higher temperatures inside the house.

A ground source heat pump (horizontal collector) is the most popular in Ireland as it's efficient and cheaper than drilling. It consists of a pipe network laid about one metre deep in the ground to extract heat from the soil; the temperature there remains constant all year round as the heat is replenished by rainwater. In good agricultural soil, pipes are laid in a trench about three feet below the surface, above the water table but below perm a-frost, giving a steady year round temperature of between 6°C to 10°C. Blue clay, yellow clay or marl are unsuitable soil conditions because they can create a waterproof layer preventing drainage and allowing rainwater to lie, with consequences of possible freezing and serious electricity bills. Dry ground makes it difficult to conduct heat and requires a much larger area of pipe work; the ideal is three feet of good dark topsoil which will retain rainwater for a time and allow it to drain away gently.

Ground source heat pumps are especially suitable for rural locations as you will need space to accommodate the loop: in a typical system 200 linear metres; 50 linear metres per kW is a good rule of thumb as that should allow you to draw heat without affecting the ecology of the garden.

Air source heat pumps consist of an above ground air evaporator that extracts heat from the atmosphere; it's important in Ireland that the evaporator be designed for high humidity air to prevent the use of electrical elements which would result in high running costs. Interestingly, a recent study backed by Enterprise Ireland and undertaken in Co. Galway has tested a device that collects energy from the moisture in the air with an innovative above ground horizontal design. This makes the heat pump not only more efficient but also does away with the need for a de-icing mechanism.

These have increased in efficiency in recent years, indeed catching up on the better COP of geothermal systems. Towns and denser urban areas have less space for pipe work and higher base temperatures so an air source heat pump will tend to benefit from this. There is though an element of noise from the fans running 24 hours to improve air flow over the heat exchanger coils which may raise an issue with neighbours.

Hydrothermal heat pumps are uncommon in Ireland. The heat is collected from a water source, which can be a pond but is most often underground; very effective if there's enough water to feed the system. Bored well collectors operate through a closed loop system which extracts heat from underground water.

How effective are heat pumps 'on the ground'?

An extensive study by the Energy Savings Trust, which ran from 200g to 2012, was undertaken to find out how heat pumps installed in UK homes were actually performing. It first evaluated 83 sites and then monitored how heat pump performance changed after various degrees of system upgrades were performed on 32 of the units. On average they found ground source performed better than air source, and in general the measured COPs stood in and around the 3 mark although in the first phase of the study one site did come in at 1.2!

Keeping the system and the controls simple was an important variable in determining which ones performed better than the rest, as was system sizing, which was especially evident in the second phase of the study, the findings of which were recently published. In five cases they had to replace the heat pump with a smaller one to increase efficiency, in another significant gains were made by altering the software to reduce the use of the auxiliary heater (COP increased from 2.31 to 3.29). This highlights the absolute necessity to get a system that is both correctly designed and installed.

What to consider

There are several critical issues to look at if you are considering a heat pump for your new home or extension. All heat pump systems depend on a highly insulated building to achieve results, which is particularly important in the case of retrofitting. Paying attention to the insulation and eliminating cold bridging is the most important requirement for a satisfactory installation. Air tightness is also important as air escaping from the house carries heat which needs to be replaced.

With C02 emissions high on the agenda, you also need to take into consideration the amount of this produced, between about 420 (NI) and 530 (ROI) g/kWh input, although the carbon content of electricity production is decreasing year on year (more renewables are being introduced and some fossil fuel power plants, especially peat, are being phased out). By programming the heat pump to operate on the electricity night tariff you'll not only save money but also the environment! To use electricity at night time is eco-friendly because there is little demand and yet the power stations are still producing energy; also wind turbines provide a lot of the power at night time.

Suitability

Heat pumps are most suited to producing low temperature (typically 35°C to 45°C), water, and are thus unsuitable for heating systems that require a high temperature input unless you add vapour injection technology. Radiators are not viable, with the exception of fan coil models or aluminium, or if your house is super insulated and therefore requires only a minimal heat input. Underfloor heating is ideal.

With regard to heating hot water for domestic use, because this is usually heated to at least 55°C (to avoid Legionella bacteria forming), there is a school of thought that if you are using a heat pump then you must have an additional method of heating the water to a high temperature in order to guard against this and also achieve the temperatures you need. Most heat pumps can accommodate additional heat sources, e.g. stove or solar panels, but it is important that the whole hot water supply side is designed correctly at the outset and in conjunction with the heating system. Both should be sized correctly to match your present and future needs. The system must also be designed to prioritise the energy sources for maximum savings.

As seen above, the latest in heat pump technology is allowing them to produce a 65°C flow, which in and of itself prevents Legionalla bacteria forming. These types of heat pumps, which use vapour injection, are therefore suitable to retrofitting and to both heating your home and producing hot water. However, bear in mind that these heat pumps haven't been as extensively tried and tested as the conventional type.

Installation costs

Heat pumps are invariably more expensive to install than oil or gas fired boilers. They also work better with large volumes of water as heat stores for the low grade heat. According to the Energy Savings Trust typical costs for the installation (excluding the cost of heat distribution) range from £9,000 (€11,000) to £17,000 (€19,000) for a geothermal system (running costs £650/€700 a year), and £6,000 (€6,700) to £10,000 (€11,000) for an air source heat pump (running costs £750/€840 a year).

In ROI grants for heat pumps were suspended while in NI the Renewable Heat Premium Payment was recently made available to homeowners and applies to a range of renewables. The Department of Enterprise, Trade and Investment (DETI) will provide you with a voucher and once you've installed the technology you can exchange it for grant money: £1,700 for air source and £3,500 for ground source.

To avail of the grant, planning permission will need to be secured in certain instances (check with your local council) and for some ground source and water source heat pumps where river or groundwater is used and then discharged back to the environment, a discharge and water abstraction licence may be needed. Other terms and conditions apply, such as having insulated your home to a high standard.

Still in NI, farmers and others who own a rural business can get up to 50% of the cost funded under the Renewable Heat Incentive by the Rural Development Fund, administered by the Department of Agriculture and Rural Development. The scheme provides financial support during the lifetime of the installation (to a maximum of 20 years) and payments are made quarterly based on the actual heat output of the system.

In a new build you can design the system to use off peak night electricity with a large well insulated heat store such as 500L buffer tanks. Using plenty of zones helps to control the space heating by not having it on where and when it isn't needed (in terms of pipe work each zone consists of one loop leading back to the manifold). When budgeting therefore, you need to take all of these aspects into consideration.

As always though, your starting point with a design should be minimising your total energy use through orientation (passive solar gain) and insulation (the U-values given in the Building Regulations are minimum values!). Above all, remember that there are considerable skills needed to install the system correctly, so allow plenty of time to do your research. The issue of payback time is one that is frequently raised by would-be green technology installers. If possible, gather 'real life' data to compare the amount of input power used (a measuring device can be plugged into the socket to do this) to the amount of power generated in kW (can be read on the heat pump controls). There are two ways of looking at this, either it's a simple equation, dividing the extra installation costs by the annual running cost savings (or, more accurately, potential savings), and should be calculated over the lifetime of the building. This should be a minimum of 50 years, but for many people the lifetime of their mortgage is more appropriate, so 20 to 25 years is a more usual figure. Electricity costs should be doubled over at least half of the 25 year period to give a true "payback" calculation, and carbon emissions counted too. You also gain under the energy rating system as a heat pump scores lower (better) than biomass. Because of the longer payback period for heat pumps, try to choose one with a good life expectancy.

Noise and siting issues

Because they require a lot of pipe work, ground based systems are not as easily accommodated in urban areas as air source. You can either lay pipe work in shallow trenches (ground required is 2.5 to three times the footprint of the house), excavated by a digger, or drill a borehole if space is tight (at an additional cost of around £3,000/€4,500) to accommodate all the pipe work, in an area as little as 2m x 2m.

Although clean, the systems are best located in a utility room for small output heat pumps or in a garage/external plant room for systems greater than 15kW, rather than in a living space because they emit a low humming noise. Care must be taken in timber frame houses as even a 10kW heat pump can be noisy. External air or water heat pumps must remain below 45db from neighbouring property and may require planning permission when installed under the N I Renewable Heat Incentive programme.

Most designs work with large water tanks, often around 200L or 300L, about double the size of a larder fridge. There are very few house designs that couldn't incorporate a heat pump but equally it is not something to fit in as an afterthought.

Choosing your heat pump supplier

There are many heat pump installers working in Ireland and the product they sell is by no means identical. Consequently, the best advice is to choose a manufacturer or company you have independent knowledge of to work with early on and, if possible, get them to design, install and commission your whole heating and hot water system; note that they should have professional indemnity insurance for designing the system. An integrated approach is especially important when you are using a variety of other heat sources. Integrating all of your M&E services in one design strategy is also a good idea as ventilation is an important factor when designing your heating system. An M&E consultant will be able to recommend which system is best for you and your home but make sure they are independent and can provide impartial advice. Talking to others who've already been 'through the loop' is rarely a waste of time.

Most importantly select a company with a good track record that has a reliable and local (in Ireland) after-sales service. Make sure you're clear why the system has been designed to a certain size and specification and how to operate the controls as this will have a considerable impact on efficiency. Heat pumps often come with a 10 to 30 year guarantee and you can expect them to last for 20 years if you carry out the required maintenance; the yearly check-up is done by the homeowner (ask your supplier about this), and approximately every two to five years the installer will have to come on site to check your system.

Requirement for three-phase electricity

Most domestic heat pumps are designed to operate on single phase power however larger houses require three phase electricity. The additional cost of three phase is extremely variable. If it is present nearby, it can often be supplied at no extra cost, and the running costs are identical to normal single-phase supplies. But on some sites the cost of three-phase supply may be many thousands of Pounds or Euros - effectively prohibitive unless you can produce it on site from PV or wind. In order to avoid having to hook your system up to a three-phase supply, you may also use a combination of two single phase pumps which operate as 'slave' and 'master'.

The Lowdown

Until very recently, heat pumps were little more than a green curio, as far as the Irish market was concerned with one or two companies committed to the technology. The efficiency of heat pumps and their recent improvements mean more and more people are considering them purely on economic grounds, and they now offer a genuine alternative to fitting a boiler. In the context of the Energy Savings Trust study, perhaps most telling is that three out of four homeowners said they would recommend a heat pump to their friends and 80% said they were satisfied or very satisfied with their system.

The reduction in the carbon emissions will also help your building energy rating (but remember to allow for the emissions produced by the electricity you use). The payback time has fallen to below ten years but it is very closely linked to the quality of the heat pump chosen and the expertise of the design and installation team. So while good installations may result in short payback periods, some systems never overcome the investment and result in replacement due to poor performance.

With companies installing heat pumps in Ireland for over 20 years, there is no doubt that the technology works (we also have the Americans and the Swedes to vouch for that!) but there is no guarantee that a heat pump will work at the efficiency it is advertised at. Whilst the efficiency ratio looks very tempting if it's 4 or more, the sums are much less pleasing when it's down near 2 (in which instance the electricity your heat pump would consume would be double). By all means consider installing a heat Pump, but pay close attention to all the details which go to make up the system. And insulate your home as well as you can afford.

Peter Bonsall, Gillian Corry & Astrid Madsen. Additional information: Tony Traill, Gerry Duffy of Eurotech Group, Castleblayney, Co Monaghan, tel. 042 9749479, www.eurotechgroup.ie

Bonsall, P., Corry, G., Madsen. Heat Pumps. Selfbuild & Improve Your Home, Winter 2013, pp48-53